Goodbye NBII, Hello NUST-i

From insightful speeches to game-changing prototypes, the NUST Innovation Day 2025 marked the launch of the university’s revitalised innovation ecosystem, NUST-i, with purpose and pride.

Hosted at the NUST Innovation Hub, the event celebrated the bold transition from the Namibia Business Innovation Institute (NBII) to NUST-i, sparking conversations on student entrepreneurship, inclusive research, and locally driven solutions.

Student innovators, faculty teams, and start-up founders brought forward fresh thinking, reinforcing a simple truth: innovation is not a buzzword, it is a tool for national transformation.

Call for Collaboration

NUST-i unites a powerful mix of programmes and platforms that fuel innovation from idea to impact. These include the Innovation Marketplace™ for startup development, the Mobile Lab for mobile and software solutions, and FABlab for product design and prototyping. Together with a suite of incubation and acceleration initiatives, they are strategically aligned with Vision 2030, the Sixth National Development Plan (NDP6),and the United Nations Sustainable Development Goals.

Speaking at the closing ceremony of the event, Hon Dino Ballotti, Deputy Minister of Education, Innovation, Youth, Sport, Arts and Culture, stated: “We are here to activate a national platform, one designed to take ideas from whiteboard to prototype, from prototype to market, and from market to measurable impact. The future we want will not be inherited. It must be built with inclusion, innovation, and shared commitment.”

NUST Vice-Chancellor, Prof Erold Naomab, added: “We are not seeking applause. We are seeking collaboration, mentorship, investment, and shared ownership of this national innovation agenda.”

Impact

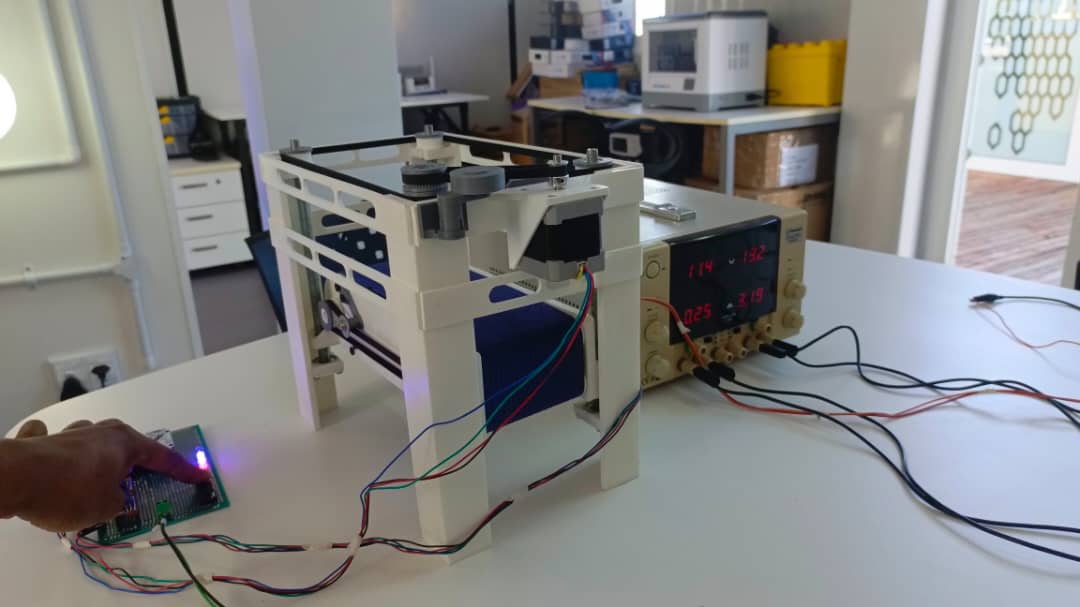

Namibian innovation continues to prove its potential to address global challenges, a vision embodied by the work of engineering student Desire Kilambo, who presented the Manufacturing and Development of a Cross Belt Metal Separation System – Kamoa Copper S.A. Case Study.

The prototype aims to improve metal separation efficiency, protect crushers from damage, reduce downtime, and lower energy consumption, all while supporting environmental sustainability.

“In a time when copper is becoming a critical ‘green metal’ for the energy transition, our innovation supports both productivity and sustainability,” Kilambo explained.